September 14, 2022

The Technical Situation

In today’s highly complex and changing marketplace, finished product suppliers, lighting specifiers, distributors and manufacturers need to be confident that the products they deliver to market meet customer expectations along with the required safety, environmental, regulatory and government standards globally. The need to meet these objectives is crucial. Non-compliant products risk being recalled, which results in being slow to the market and costly. Poor quality products or misrepresented performance can result in customer dissatisfaction and product returns. Both can negatively impact brand image.

The Challenges, and Labsphere’s Action

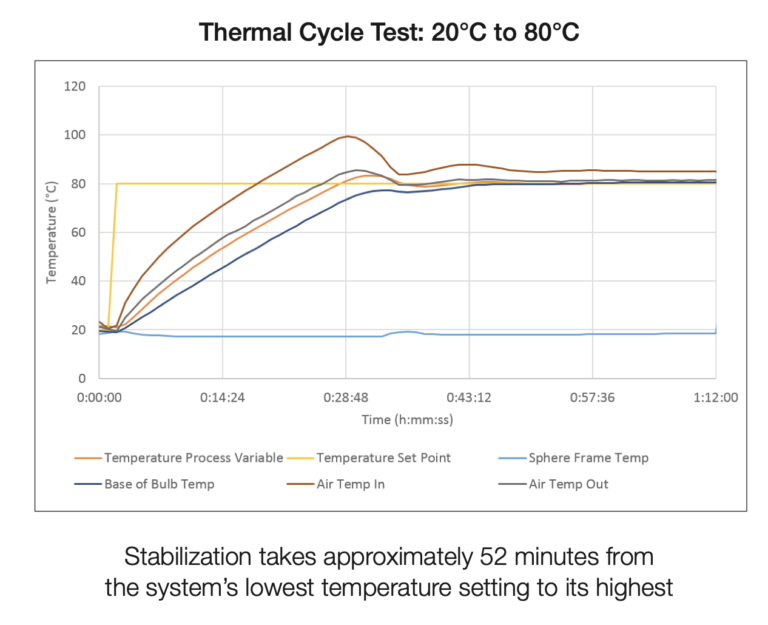

When developing a solid-state light engine to be used in an environment where excessive temperatures may affect it, it may be necessary to have data of the spectral output relative to its temperature. This requires a system that can measure total spectral flux over a range of temperatures.

Testing, calibration and qualification are important requirements to ensure confidence in reported specifications. The testing process begins with understanding the product, procedures and the appropriate equipment necessary to achieve desired results.

The Results

In this case, a leading global testing laboratory recognized the importance of reliable equipment and software to ensure compliance reporting quickly and reliably with the installation of two illumiaPlus Temperature Controlled Light Measurement Systems. This decision enabled them to confidently provide comprehensive testing services for lamp and luminaire manufacturers and distributors.

- Enables the testing laboratory to perform qualification tests compliant with IES LM-79, IES LM-78 and LM-82

- The system offers outstanding stability over time, producing accurate results during lengthy tests

- The flexibility of the design allows the laboratory to test almost any light source, including fluorescent lighting, LEDs, troffers, headlights, and more

- The testing process is facilitated with Labsphere’s Integral® software:

- Automated calibration routines make initial setup fast and easy

- Allows user to generate custom data reports using templates in Excel, saving ample time and effort

- User can access and control multiple test stations at once

- Control over every piece of hardware, including both inputs and outputs

- UI that is easy to read and use