October 24, 2023

Introduction

A manufacturer of high-power laser diode arrays, diode-pumped laser gain modules, and diode-pumped solid-state lasers was facing challenges in improving pump efficiencies and beam uniformity for their quasi-continuous wave (QCW) pulsed pumped laser diode modules.

Objective

They needed a pump chamber reflector component that was unique to their design. The component also needed to have high reflectance, be uniformly diffuse, durable, and resistant to damage at their pump chamber energy levels.

![]() Implementation

Implementation

The laser manufacturer chose to work with Labsphere which specializes in developing customized OEM solutions. We collaborated closely with the manufacturer to understand their specific needs and requirements, with quick turns on prototyped components to develop a solution that met their needs.

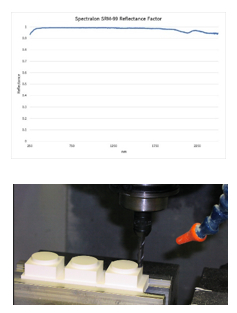

Labsphere used its advanced material Spectralon SRM-99 and manufacturing and machining techniques to develop diffuse pump chamber reflectors that met the manufacturer’s performance requirements. The reflectors were also designed to be easy to install and maintain, with features that allowed for quick and easy replacement in case of damage.

To ensure quality, the Labsphere implemented rigorous cleanliness and part inspection processes throughout the development and production process.

Results

The manufacturer’s QCW laser diode modules are designed to provide high-power, pulsed laser output for airborne LIDAR, laser pulse train amplification, laser peening, flow diagnostics, and OPCPA pumping. Labsphere was able to deliver application-specific diffuse reflector components that meet the laser manufacturer’s performance, quality, and cost requirements. Our diffuse reflectors are successfully integrated into the manufacturer’s QCW laser diode module series and help to differentiate their brand in the market. In addition to laser output power and energy efficiencies, the high performance of our Spectralon diffuse reflectance material provides a significantly enhanced and more predictable beam quality compared with less diffusely reflecting materials as a direct result of the more uniform pumping of the laser medium. The laser output parameters that are affected include improved spatial uniformity; reduced non-symmetrical optical aberrations (coma and astigmatism); and reduced ‘hotspots’.

Conclusion

Overall, the collaboration between the laser manufacturer and Labsphere resulted in a successful series of products that meet the manufacturer’s specific needs and help them to stay competitive in the market through multiple generations of their laser diode modules.