Imaging, Sensing & Remote Sensor Calibration Solutions

Uncover our diverse range of spectral radiance and irradiance reference sources, which include broadband, narrowband, and spectrally tunable options. These sources are designed for the characterization and calibration of imaging and non-imaging components and systems across consumer, industrial, defense, and scientific domains. Our solutions empower customers to conduct essential tasks such as spectral response analysis, spectral modeling, flat fielding, white balance adjustments, optical systems corrections, display illumination, and more to meet the rigorous demands of today's image and data-oriented markets.

Create: Imaging, Sensing & Remote Sensor Calibration Solutions

Showing 1–12 of 15 results

-

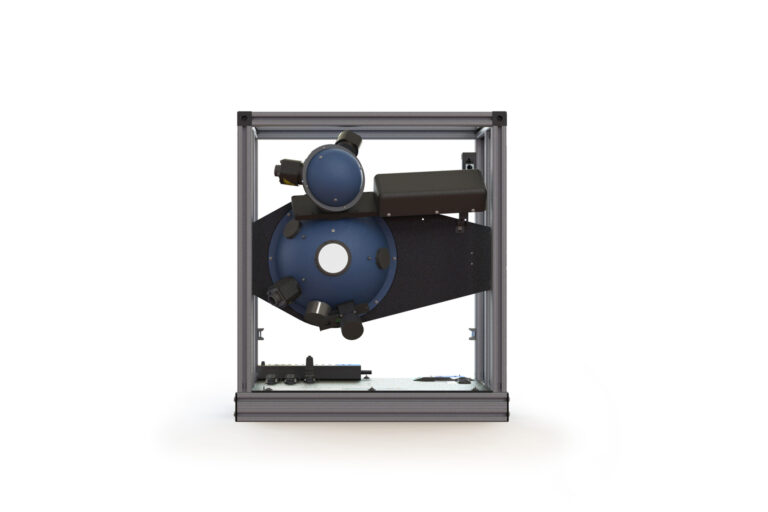

Blue Sun Uniform Source

-

Spectra-PT Power Tunable Portable Luminance Test and Calibration Reference Source

-

Spectra-CT Color Tunable Test and Calibration Reference Sources

-

Spectra-FT Fine Tunable Test and Calibration Reference Sources

-

Spectra-UT Ultra Tunable Test and Calibration Reference Sources

-

Spectra-PT Power Tunable High Dynamic Range Test and Calibration Reference Sources

-

Spectra-QT Quantum Tunable Irradiance/Radiance Calibration Source

-

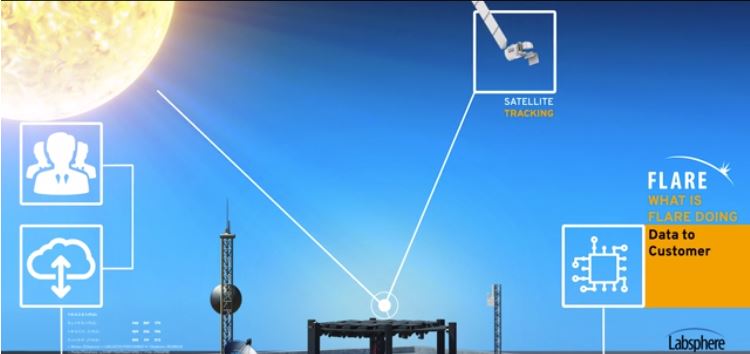

FLARE Vicarious Calibration Network

-

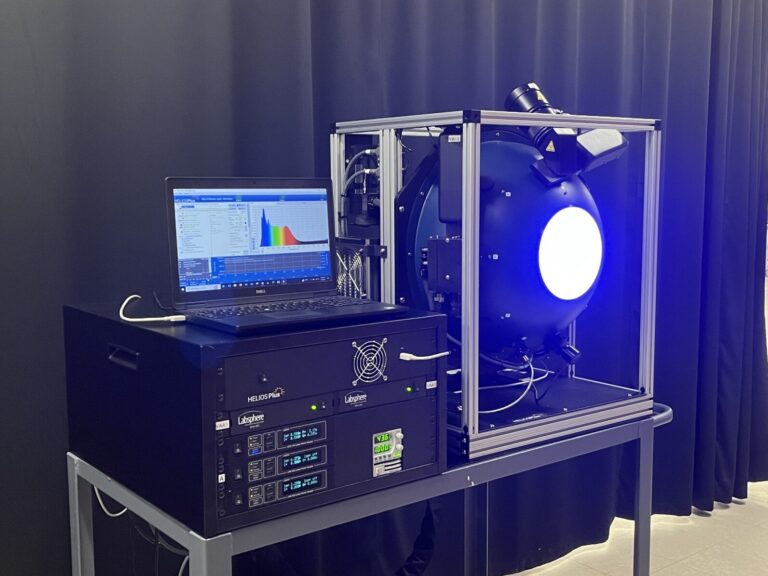

HELIOS®Plus-AMA Air Mass-Albedo Sunlight Systems

-

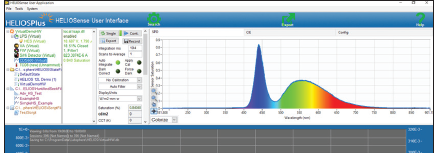

HELIOSense® Software

-

HELIOS® Plus-LL Low Level Systems

-

HELIOS® Plus-DR High Dynamic Range Systems

Cameras are now a ubiquitous part of our lives. Their purpose ranges from capturing simple images for entertainment to sophisticated hyperspectral imagery for remote sensing data analysis. Yet in all the applications that span this gamut, a high-quality image is the expectation of the user. Achieving this, and providing meaningful, quantitative information behind the image is the result of careful calibration and characterization of the imaging sensor.

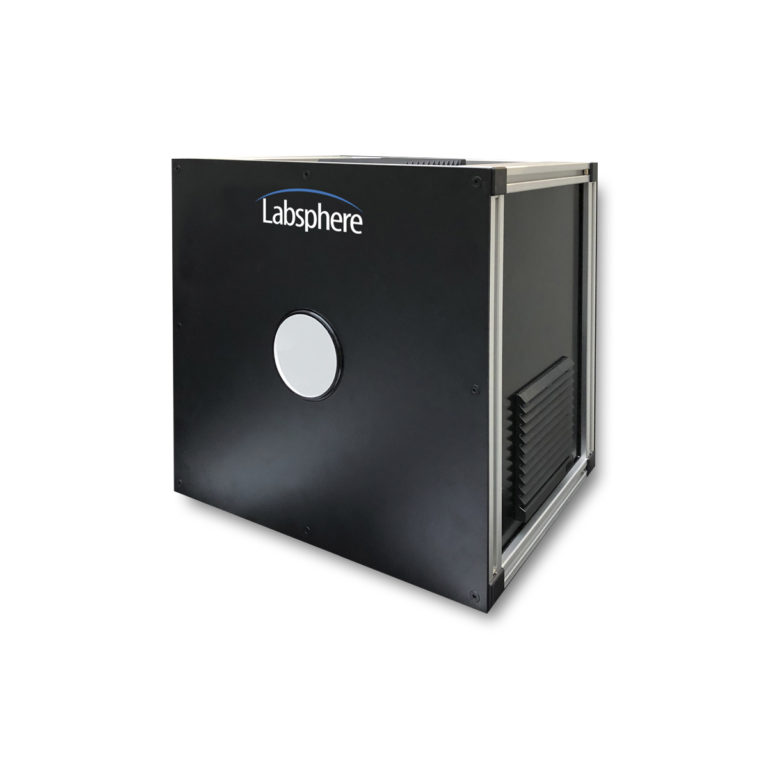

Labsphere provides uniform light sources that allow the response of the sensor to be characterized and the image perfected. This response will differ for the use-case and the environment in which the image is captured. Because of this, it is necessary to characterize the image sensor using the same spectral content that it will see in its intended application.

For example, cell phone cameras are used in conditions with widely-varying lighting conditions: outdoors, indoors, at night, under water, at concerts, etc. Getting the best image involves testing under these conditions and then performing the image processing based on this characterization. Labsphere creates the light sources that can match these conditions which allows the calibration and characterization that enables the highest possible image.

While most cameras use sensors that are filtered for red, green and blue, scientific instruments will use monochromatic (single wavelength), multi-spectral, or hyperspectral sensors to extract wavelength-specific information from the scene. For demanding applications, it can become critical to investigate the sensor response as a function of each wavelength in the sensors range.

In addition, imagers for space and high-altitude aerial applications operate in extreme environments of low/high temperature and vacuum. This alters the performance of the sensor and hence, the calibration and characterization need to be done in this environment to ensure high performance when in flight.

Performance Options

Given these wide operational and environmental conditions, Labsphere has created a range of

systems that can address needs. All systems are designed to provide uniform light fields. The

range of performance changes in terms of the requirements:

- Low Levels (night visions and dim conditions)

- High levels (solar simulation, saturation effects)

- UV-VIS-NIR-SWIR

- Fixed spectra

- Tunable spectra

- Wavelength sweeps

- Monochromatic (Laser lines)

- Hi/Low Dynamic Range

- Small/large illumination areas

- Production line applications

- R&D applications

- Vacuum compatible

Light Source Choices

- RGB LEDs

- Tunable/Selectable LEDs

- QTH (Quartz Tungsten Halogen Lamps)

- Xenon Lamps

- Tunable Lasers

- Laser-excitation plasma sources

- Super-continuum lasers

Measurements Using the Uniform Light Source

Flat Fielding and Fixed Pattern Noise (FPN)

Since the output from the uniform source is a unform light field, imaging this source should result in a perfectly uniform image where every pixel registers the same value. By using the uniformity map provided by Labsphere, the image can be corrected and the correction matrix can then be applied to future captures. Since this correction may be a function of wavelength, levels, and spectra, the corrections can be made for whatever environment is anticipated.

This correction removes any fixed pattern noise FPN, and then corrects for systematic variability between the sensors in the array. By performing this flatfield at a range of input levels, the Photo Response Non-Uniformity, PRNU, can be calculated. This measurement characterizes how the pixel-pixel deviations vary over the range of light levels which can then be used for image correction.

Spectral Response

The array of sensors in the imager respond to the stimulus of light input by providing an output in terms of current or digital number, DN. This varies with wavelength and intensity, so by characterizing this response to a known input (the Labsphere source) the sensor output can be related to an absolute value of the stimulus when used in the field. If filters are used on the sensor, they will only respond to the light that the filter passes through. These filters can be made for simple red, green, blue cases, band passes, or filtered to represent the photopic response curve, V(l). Be exposing the sensor to a range of light inputs, it can be calibrated for a known input of radiance, if a lens is used, or irradiance for a bare sensor.

By sweeping the light through the range of wavelengths, the sensor output can be measured to

detail how it responds to specific wavelengths of light. This can be done by using a series of

lasers, tunable lasers, or a monochromator outfitted with a broadband light source. In each case the source is brought into the integrating sphere to create the spatially uniform light field for the sensor calibration.

Dynamic Range

Sensor dynamic range is the ratio between the highest and lowest signal that the sensor can measure. Labsphere’s uniform sources can be used to test the dynamic range of the sensor at a variety of wavelengths and spectra. It can be used to determine the noise floor as well as the saturation limits of the sensor.

Linearity

The linearity of the sensor response describes how well the output varies with changes in the input levels. Similar to dynamic range testing, the response of the sensor to variations in input levels can be used to define the linearity. A sensor is typically linear over a certain range, so this test can be used to not only define the linear range, and the calibration constant, but also the calibration values when the linear range of the sensor is exceeded.

White Point

By mixing red, green, and blue sources in different proportions, white light can be created where the chromaticity values (x, y) or (u’, v’) fall on different parts of the Planckian locus on the chromaticity diagram. Adjusting these ratios can move this white point along the Planckian curve to allow for testing of optical elements. Using sources at a particular white point can be used to illuminate displays to test performance under a range of ambient illumination scenarios. Throughput of optical elements such as wave guides, lenses, mirrors and other components can also be done to evaluate losses and performance.

Colorimeter Calibration

Colorimeters are used to measure the chromaticity of various sources, materials, and objects. The source spectrum is measured by a series of sensors that are filtered over specific bands, or from a spectroradiometer that has many narrow bands over the visible spectrum. In each case, the emitted radiance is convolved with the sensor spectral response to determine the color coordinates, or chromaticity of the measurement. For active sources, this leads directly to the (x,y) or (u’, v’) chromaticity values. For materials, the light source used to illuminate the material will change the reflected radiance of the measurement, so understanding the light source is important as well.

Errors in the measurements are minimized for devices that measure the complete spectrum because the narrow bands of the sensor elements can distinguish the variations in the radiated spectrum from the source. For instruments that used RGB sensors, errors can become large when extracting the chromaticity values due to spectral mismatch between the radiant source and the spectrum used for the instrument calibration. This happens because the three sensors span a wide spectral band, and an infinite number of incoming spectra can create the same value of the convolution between the incoming radiance and the sensor response. To minimize this spectral mismatch, the colorimeter needs to be calibrated with a source of known spectral radiance that matches the spectral shape of the source to be measured. This is where Labsphere’s tunable uniform sources can be invaluable.

For production line applications where the color performance of a display is to be measured, the tunable source can be used to match the spectral output of the displays. Using this as the calibration source, the measured chromaticity of the displays going down the production line can be accurately assessed. The reference source can then be modified to cover a range of possible display settings allowing the manufacturer to test a host of operating conditions.